Suzhou Player Machinery Equipment Manufacturing Co., Ltd. is a manufacturer of special vehicles and equipment.

read more

+86-+86-15895439421

Description:The power for this simulation train is optional. Since there are different traveling route situations, two kinds of power are available. I...

See Details

Description:The power for this simulation train is optional. Since there are different traveling route situations, two kinds of power are available. I...

See Details

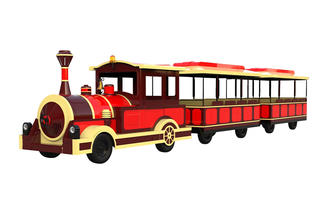

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details

Description:For this tourist trackless train, its classic design makes you feel like you are traveling on a 1900s steam engine train. It’s ideal for c...

See Details